Clothing and Cap Embroidery

When most people think of embroidery they probably think of a grandparent or some other "crafty" family member or friend sitting in a chair with some fabric clamped in a frame. Along with a needle, thimble & a piece of very long thread. This idea is pretty much correct, except now we use machines to do the work!

Stemming from ye olden days of monogramming (placing your initials on clothing) using only a needle, a thread & a well calloused thumb, embroidery is still the most popular branding method for uniforms & headwear. Of course now technology allows us to be more creative than just having our initials on a shirt or handkerchief.

In some respects though things haven't changed much - it still is quite literally a needle & thread, just more of them, moving at much faster speeds all controlled by a computer & a big machine.

The greatest strength of embroidery is that it uses the same raw material as the garment (a thread), to add the branding. Done well, it integrates seamlessly, looks professional & will remain in good condition for the life of the garment.

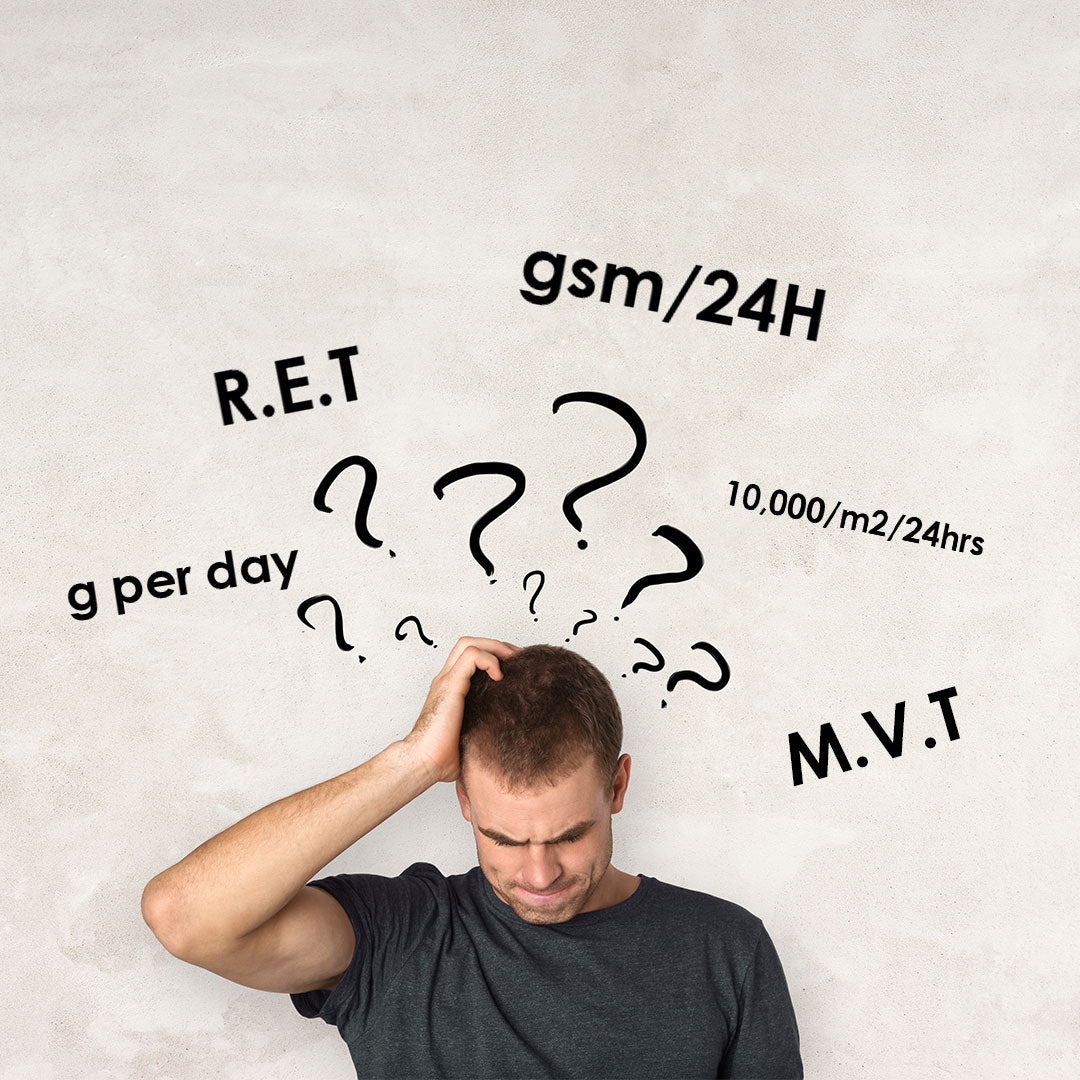

The quality of a finished embroidery is the result of a combination of variables, some of which are more controllable than others. Variables that influence successful outcomes include :

-

The brand of thread used | Like most things there's a wide range of "qualities" when it comes to embroidery threads. Better quality threads cost more but produce better results. At House of Uniforms we exclusively use King Star embroidery threads. King Star threads are known for their quality, vibrance & durability. Ensuring your branding stays sharp & vibrant for the life for your uniforms.

-

The type of backing used | All embroideries (well those that have been done properly) have on the reverse side of the garment a backing or stabiliser. This is essential as it provides stability to the embroidery preventing it from loosing shape. It also helps produce a consistent surface for the needle to pass through, there by reducing the chance of loops & distortion. Like threads there is a wide range of backing quantities available. Most commonly used it a type of backing called "tear away". As the name suggest the backing is simply pulled / torn away from the garment once the design has been applied. This is a budget solution as tear away backing is cheaper to buy & far less labour intensive to work with. However it provides less stability & distortion to your artwork can be caused simply by the removal of the backing. At House of Uniforms we use cut away backing. Cut away backing is time consuming & much more expensive compared to tear away backing but the results are superior. Cutaway backing it also softer against the skin making it more comfortable to wear. With cutaway backing when the embroidery is completed the machine operator must take a pair of very sharp scissors & carefully cut the backing away from the garment. This takes time. But we believe it's worth it to ensure our customers logos look as good as they possibly can. Our backing is imported from the USA ensuring our customers are getting the very best quality.

-

The embroidery machine | Not all embroidery machines are created equally. At House of Uniforms we use state of the art digital multihead Barudan embroidery machines. Made in Japan, Barudan is a global leader in the development of embroidery machines. Like a vehicle, embroidery machines needs constant maintenance to ensure they keeping running reliability with consistent output. Our machines start each day with a mechanical check, oiling, high pressure air blast out & needle check. Each of our 8 head machines contains 144 needles so it's quite a task when these need replacing & rethreading!

-

Digitising | Another key element in the final result for your embroidery is the digitising. Digitising refers to the process of taking your artwork or logo & rendering it so that the embroidery machine can read & understand how to output it. This includes assigning thread colours to your logo & in turn allocating needles to your design so that the right thread colour gets pulled through by the right needle, at the right place in your design. The process of digitising can be thought of more like painting a picture. No two people will create exactly the same digitised file. Which is why there will most likely always be variance between a file setup by one person & the same file setup by another person. Digitising is a specific skill, it can be done poorly or very well depending on the experience of the digitiser. Once your logo has been approved we lock the approved design into our machine for future use to ensure consistency over repeat orders.

- Artwork | not all artwork works well as an embroidery. Logos with very fine lines, gradients of colours, wispy bits, tiny text & other dots look messy & usually require some reconfiguration to ensure a good result.

While embroidery is the most popular branding method, due to it's versatility over a range of fabrics, it does have limitations. Embroidery is achieved by weaving a single coloured thread through a garment (rather than sitting on top the fabric like most modern printing methods) meaning there is a limit to the level of detail that can be achieved. Fine lines obviously are limited to the width of the embroidery thread. A thread is a solid colour so it can't start off blue & end up pink, so gradient colours can't easily be achieved.

As embroidery uses threads there is a finite range of colours available. Sometimes it may not be possible to match exactly a colour you are wanting, if the thread colour doesn't exist it simply can't be created.

Click here to learn more about embroidery & our other branding options.

Easy Explainers | Load Up On Learnings

- Choosing a selection results in a full page refresh.

Footer menu

House of Uniforms

Office & Showroom: (appointments essential)

4 Walter Street, Moorabbin 3189, Victoria, Australia

T: 03 95557797

E: info@houseofuniforms.com.au

Please contact us to make an appointment.

Want Deals & FREE Stuff?

Deals & Freebies

are for our amazing subscribers only.

_____________________________

Sorry there's NO Auto :

- free shipping coupons,

- 10% intro vouchers

- Or any other generic offers

Why Subscribe? Well, we love spoiling our subscribers, we're known to be very generous. So go ahead hit subscribe; You'll love being part of our exclusive group.

Don't want to Subscribe? That's totally fine. You can still shop with us, you just won't receive any special offers, deals or freebies.

Bulk Discounts are for everyone (subscribed or not).

© 2026, House of Uniforms Powered by Shopify

!